Plant wax is an important raw material. In industry, it can be used to make insulating coatings for electrical appliances, wetting agents for leather, wood, and paper, polishing agents for cosmetics, home furnishings, floors, etc., wax paper, crayons, carbon paper, shoe polish, lubricants for precision instruments for high-temperature operations, etc.; in food processing, it can be used as a preservative for fruit spraying, etc.; in medicine, it can be used for the packaging of medicinal wax pills, etc. Especially in food processing and medicine, it cannot be replaced by mineral wax, because the harm to the human body must be considered. Therefore, removing and extracting wax from oil can not only improve the quality of edible oil, but also improve the industrial utilization value of oil and fat and the purpose of comprehensive utilization of plant oil wax sources.

What does wax in vegetable oil refer to?

There is a small amount of wax in vegetable oil, which is a mixture of esters formed by high molecular fatty acids, monohydric/dihydric alcohols and natural carotenoids. When producing edible oil, oil mills will use a variety of processes to remove wax from edible oil. This is because wax has a high melting point and is easy to form a very stable fine crystalline suspension in the oil. Even if the oil does not contain stearin, it will cause poor transparency and quality. Therefore, the wax in the oil will be removed by refining and dewaxing equipment during production.

Dewaxing is not a necessary process for edible oil, but it is an indispensable process for improving the quality grade of oil and producing high-grade national standard edible oil.

Principle of edible oil dewaxing:

The presence of acyl groups in wax molecules makes the wax slightly polar. Therefore, wax is a lipophilic compound with a weak hydrophilic group. When the temperature is higher than 40°C, the polarity of wax is weak and it dissolves in oil. As the temperature drops, the mobility of wax molecules in the oil decreases, and the ester bond in the wax molecules increases. Especially when it is lower than 30°C, the wax forms crystals and precipitates, and becomes a stable colloidal system. After a period of time at this low temperature, the wax crystals condense into larger crystals, increase their specific gravity and become a suspension. Then, the crystallized wax is filtered out by filtering equipment to obtain dewaxed edible oil.

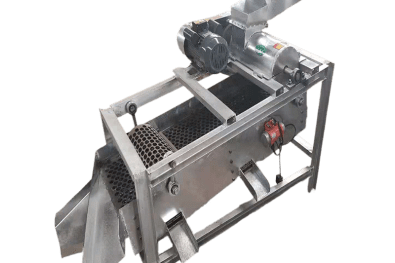

Edible oil dewaxing equipment usually consists of a variety of equipment such as crystal crystallization tanks, filters, dewaxing oil tanks, wax paste boxes, refrigeration units, frozen brine pools, gear pumps, pipeline pumps, etc. The complete set of oil dewaxing equipment produced by our company uses 304 stainless steel as raw material, which is durable and corrosion-resistant, and the oil is not contaminated, ensuring the health and hygiene of the oil.