Oil cleaning is to clean up the impurities such as mud, sand, metal, stems and leaves in the oil, and separate the mixed seeds and empty seeds mixed in the oil. In the process of harvesting, drying, transportation and storage, oil is inevitably mixed with some impurities such as stones, mud, stems and leaves, and hemp ropes. Although it has been preliminarily selected, it will still carry some impurities when it is transported to the oil mill, and its content is generally about 1%-6%. These impurities are extremely unfavorable for oil production and need to be cleaned.

The impurities contained in oil are nothing more than three categories: inorganic impurities, organic impurities and oil-containing impurities. Inorganic impurities are mainly dust, mud, stones, tiles, metals, etc.; organic impurities are mainly stems and leaves, skins, wormwood, hemp ropes, various grains, etc.; oil-containing impurities are mainly diseased and insect-infested grains, unreal grains and heterogeneous oils, etc.

Purpose of cleaning: The oil put into processing should be cleaned to remove all kinds of impurities and provide favorable help for subsequent oil production.

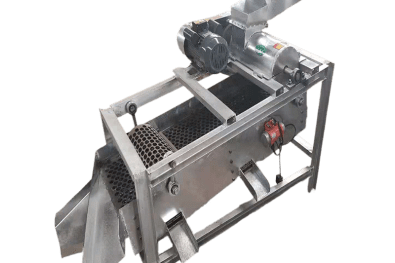

Raw material cleaning equipment can play the following roles in edible oil production lines:

1. Improve oil yield: By screening out useless impurities in the oil, ensure that more oil can be extracted and reduce the situation where the oil is adsorbed and taken away by impurities, thereby directly improving production efficiency and economic benefits.

2. Improve product quality: Screening out non-oil materials can reduce the sediment in the crude oil, making the output oil clearer and purer, while improving the quality and application range of cake as a by-product.

3. Protect production equipment: Screen out hard impurities such as stones and metals to avoid damage to high-speed and high-pressure equipment, reduce equipment maintenance costs and unexpected downtime.

4. Avoid production accidents: Avoid damage or safety accidents caused by hard objects such as metal fragments entering key equipment, as well as blockages and failures caused by long fiber impurities, to ensure safe and continuous production.

5. Improve processing capacity: Reducing the proportion of impurities can increase the processing capacity of oil, allowing the equipment to process more useful raw materials at the same time and improve overall production capacity.

6. Optimize the working environment: Reducing dust and impurities not only improves the environmental hygiene of the factory, but also protects the health of workers, avoids potential dust explosion risks, and improves job satisfaction and production quality.

In summary, raw material cleaning equipment is an indispensable part of the edible oil production process. It removes various impurities in the oil, laying a good foundation for the subsequent oil production process, ensuring product quality, production efficiency and safety.