Edible oil refining refers to the process of performing a series of treatments on crude oil to remove impurities and undesirable components and improve the quality of the oil.

The main purposes of oil refining include:

1. Improve the stability of oil: extend the storage period of oil.

2. Improve the color and smell of oil: make it more in line with consumer needs.

3. Remove harmful substances: such as heavy metals, pesticide residues, etc.

4. Improve the purity of oil: meet the requirements of different uses.

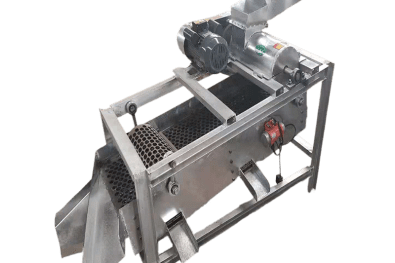

Refining equipment Oil refining usually includes the following steps:

1. Degumming: remove phospholipids and other colloidal impurities.

2. Deacidification: Reduce the acidity in oil.

3. Decolorization: remove impurities such as pigments.

4. Deodorization: Remove bad odors.

5. Dewaxing: suitable for certain oils, such as rice bran oil.

Through these refining steps, edible refining equipment can obtain high-quality refined oil that meets market demand and relevant standards. Chemical reagents used in the refining process may cause certain harm to the human body, depending on the following factors:

1. Type and concentration of chemical reagents: Different reagents have different toxicities.

2. Mode and time of exposure: Long-term exposure or high-concentration exposure may increase the risk.

3. Personal health: Sensitive groups may be more susceptible.

In order to reduce the risk of edible refining equipment, it is recommended that you take the following measures:

1. Strict operating procedures: Ensure workers use and handle chemical reagents correctly.

2. Personal protective equipment: such as gloves, masks, etc.

3. Ventilation system: prevent the accumulation of chemical reagents.

4. Safety training: Improve workers’ safety awareness.