Several factors influence the effectiveness of oil extraction, whether from coconuts or other sources like seeds and nuts. Here’s a breakdown of key factors that affect the oil extraction process:

- Raw Material Quality

- Moisture Content: The moisture content of the raw material affects oil extraction. Optimal moisture levels are required to ensure efficient pressing. Too much moisture can lead to lower oil yields and hinder pressing efficiency.

- Ripeness and Freshness: The maturity of the raw material can influence oil yield and quality. Overripe or decayed materials can reduce the quality of the extracted oil.

- Variety of Source Material: Different varieties of coconuts or oilseeds can have varying oil content and extraction properties. Choosing a high-oil-content variety can improve yield.

- Extraction Method and Equipment

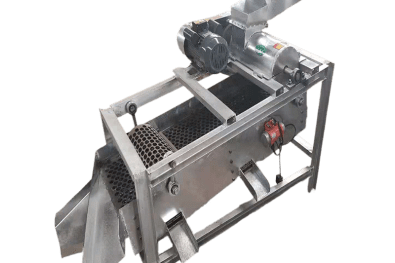

- Type of Pressing Equipment: The kind of press used, whether it’s a cold press, expeller press, or solvent-based extraction, affects efficiency and yield. Different methods may require different adjustments for optimal performance.

- Operating Conditions: Factors like temperature and pressure play a crucial role in the extraction process. Proper control of these conditions can enhance oil yield and quality.

- Equipment Maintenance: Proper maintenance and cleanliness of the equipment can affect extraction efficiency. Well-maintained equipment ensures smooth operation and reduces contamination risks.

Vegetable Oil Extraction Line - Pre-processing and Preparation

- Drying and Conditioning: Proper pre-treatment of raw materials, like drying and conditioning, can significantly affect extraction. Drying to the correct moisture content and removing impurities can lead to better extraction results.

- Size Reduction and Dehusking: Reducing the size of the raw material and removing husks or shells facilitates more efficient pressing. Proper size reduction allows for better oil release during extraction.

Oilseed Pretreatment - Post-extraction Processing

- Oil Filtration and Refining: After extraction, processes like filtration and refining can influence the quality of the final oil product. Proper filtration removes impurities, while refining can improve the oil’s color, taste, and shelf life.

- Storage and Handling: Proper storage conditions, including temperature and container type, help maintain oil quality. Exposure to air, light, or contaminants can degrade the oil’s quality over time.

- External Factors

- Environmental Conditions: Humidity, temperature, and other environmental factors can impact both the raw material and the extraction process.

- Labor and Expertise: The skill and experience of the personnel operating the equipment and handling the extraction process contribute to overall efficiency and quality.

- Compliance and Regulations: Meeting local and national regulations, including safety and environmental standards, can influence how extraction is conducted and the level of oversight required.

These factors all contribute to the effectiveness of oil extraction and should be carefully managed to achieve optimal results in terms of both yield and quality.