In rapeseed oil processing, both the quality of the oil and the technology used are crucial to ensure efficient production and high-quality output. Here are some key aspects of the oil and the technology involved:

Quality of Rapeseed Oil

1. Nutritional Benefits:

– Rapeseed oil, also known as canola oil, is rich in omega-3 and omega-6 fatty acids, which are essential for heart health. It also contains a good balance of monounsaturated and polyunsaturated fats.

2. Low Erucic Acid:

– Modern rapeseed varieties have been bred to contain low levels of erucic acid, making the oil safe for human consumption. High erucic acid levels can be harmful, so this is an important quality characteristic.

3. Processing Impact on Quality:

– The processing method significantly affects the oil’s quality. Cold pressing retains most of the nutrients and is considered superior for producing high-quality oil. However, refining processes are also necessary to remove impurities and improve the oil’s shelf life and taste.

Technology of Rapeseed Oil Processing

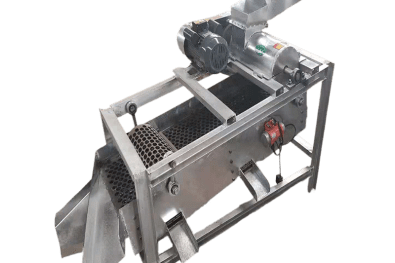

1. Cleaning and Dehulling:

– The first step involves cleaning the seeds to remove impurities such as stones, dirt, and other debris. Dehulling is then performed to remove the seed coat, which improves oil yield and quality.

2. Conditioning and Flaking:

– Seeds are conditioned by heating to make the oil extraction process more efficient. Flaking involves pressing the seeds into thin flakes, which increases the surface area for oil extraction.

3. Pressing:

– There are two main methods of pressing: cold pressing and hot pressing. Cold pressing uses lower temperatures and is preferred for retaining nutrients, while hot pressing involves higher temperatures, which can increase yield but may reduce some nutritional qualities.

4. Solvent Extraction:

– For large-scale production, solvent extraction using hexane is common. This method extracts more oil than pressing alone but requires subsequent refining to remove solvent residues and other impurities.

5. Refining:

– The refining process includes degumming, neutralization, bleaching, and deodorization. These steps remove free fatty acids, phospholipids, pigments, and odorous compounds, resulting in a clear, neutral-tasting oil suitable for cooking.

6. Winterization:

– This process removes waxes that can cloud the oil at low temperatures. It is particularly important for oils that will be used in salad dressings or other applications where clarity is desired.

Importance of Both Elements

– Synergy Between Oil Quality and Technology:

– The use of advanced processing technologies ensures that the inherent qualities of the rapeseed oil are preserved or enhanced. Efficient extraction and refining processes result in higher yields of high-quality oil.

– Consumer Health and Market Demand:

– High-quality rapeseed oil that retains its nutritional benefits meets consumer demand for healthy cooking oils. Advanced technology enables producers to meet these demands efficiently and economically.

By focusing on both the quality of the rapeseed oil and the technology used in its processing, producers can ensure they deliver a product that is not only nutritious and safe but also economically viable and competitive in the market.