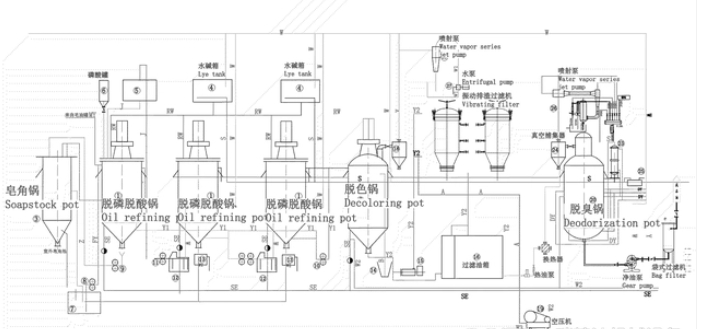

The principle of a soybean oil refining machine involves the purification and transformation of crude soybean oil into refined, edible oil that meets quality standards for consumption. The refining process is typically divided into several stages: degumming, neutralization, bleaching, and deodorization. Here’s how each stage works:

1. Degumming

Purpose: The degumming process is designed to remove gums (phospholipids) and other impurities such as proteins and carbohydrates that are naturally present in crude soybean oil.

Process: Water or acid (phosphoric acid) is added to the crude oil, which causes the phospholipids to become hydratable. These are then separated from the oil using centrifugation. The result is a partially purified oil with reduced gum content.

2. Neutralization

Purpose: This step removes free fatty acids (FFAs) that can cause the oil to become rancid and degrade its quality.

Process: An alkali solution (usually sodium hydroxide) is mixed with the oil. The alkali reacts with the FFAs to form soap, which is then separated from the oil by centrifugation. This step also helps to remove some pigments and other impurities.

3. Bleaching

Purpose: The bleaching process removes color pigments (such as chlorophyll and carotenoids), traces of metals, and other impurities to improve the color and stability of the oil.

Process: The oil is mixed with bleaching earth or activated clay, which adsorbs the pigments and impurities. After mixing, the oil is filtered to remove the bleaching agent along with the adsorbed impurities.

4. Deodorization

Purpose: Deodorization is used to remove volatile compounds that cause off-flavors and odors, resulting in a neutral-tasting and odorless oil.

Process: The oil is heated under vacuum conditions, and steam is passed through it. The steam distillation process removes the volatile compounds, including free fatty acids and other odor-causing substances.

5. Winterization (Optional)

Purpose: This optional step is used to remove waxes and other high-melting-point triglycerides that can cause the oil to become cloudy at low temperatures.

Process: The oil is slowly cooled to allow the waxes to crystallize, and then it is filtered to remove the solidified waxes.

6. Final Filtration and Storage

Filtration: After refining, the oil undergoes final filtration to ensure all remaining particles and impurities are removed.

Storage: The refined soybean oil is then stored in clean, stainless steel tanks, ready for packaging and distribution.

Key Points:

Purity: The refining process is designed to produce oil that is free from impurities, has a neutral taste, and is safe for consumption.

Stability: Refined soybean oil has a longer shelf life due to the removal of free fatty acids and other unstable components.

Quality: The process ensures the oil meets regulatory standards for edible oils, including appearance, odor, and nutritional content.

These steps are typically automated in modern refining machines to ensure consistent quality and efficiency in large-scale oil production.