The 20TPD rapeseed oil refining equipment integrates key steps in the refining process, such as degumming, deacidification, decolorization, deodorization, etc., which can significantly improve the quality and stability of edible oil. However, to ensure proper operation of the equipment and excellent quality of the refined canola oil, here are some key considerations:

1. Raw material quality control

Ensure that the rapeseed oil raw materials entering the refining equipment are of stable quality, free of impurities, excessive moisture, and in compliance with production standards. The quality of raw materials directly affects the quality of refined oil products. Therefore, strict screening and pretreatment of raw materials are the basis for ensuring the refining effect.

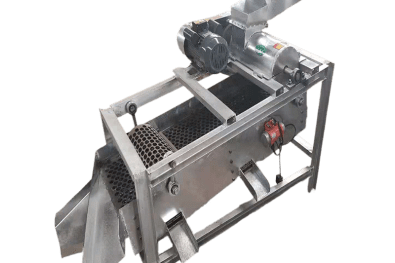

2. Equipment status check

Before starting production, you should carefully check whether all parts of the refining equipment are intact, such as mixers, heaters, filters, etc., to ensure that they are in normal working condition. At the same time, the sealing performance of the equipment must also be checked to prevent oil from leaking during the refining process. This step is crucial to prevent equipment failure and ensure production safety.

3. Process parameter control

Process parameters such as temperature, pressure, and stirring speed during the refining process need to be accurately controlled according to different refining stages. Small changes in these parameters may have a significant impact on the refining results. Therefore, operators need to have certain professional knowledge and experience to ensure the accuracy and stability of process parameters.

4. Safety protection measures

Refining equipment may produce dangerous factors such as high temperature and high pressure during operation. Therefore, it is necessary to ensure that the safety protection facilities around the equipment are intact and conduct regular safety inspections and maintenance. In addition, operators should strictly abide by safe operating procedures and wear necessary protective equipment to ensure personal safety.

5. Equipment maintenance and upkeep

After long-term operation of the refining equipment, regular maintenance and upkeep are required, such as replacing worn parts, cleaning filters, checking electrical circuits, etc. These measures can ensure long-term stable operation of the equipment, extend the service life of the equipment, and reduce maintenance costs.

6. Quality inspection and monitoring

Conduct quality testing on the refined rapeseed oil, including testing of acid value, peroxide value, color, odor and other indicators to ensure that the product meets relevant standards and requirements. At the same time, a complete quality monitoring system should be established to monitor and adjust the production process in real time to ensure the stability and consistency of product quality.

7. Employee training and technical support

Regularly provide technical training and guidance to operators to improve their operating skills and equipment maintenance capabilities. In addition, the company should provide timely technical support and services to help solve various problems and difficulties encountered during the production process.

In summary, the use of 20TPD rapeseed oil refining equipment requires attention to many aspects, including raw material quality control, equipment status inspection, process parameter control, safety protection measures, equipment maintenance and upkeep, quality testing and monitoring, and employee training and technology support, etc. Only by strictly complying with these precautions can the normal operation of the equipment and the excellent quality of refined rapeseed oil be ensured.