Rice bran oil processing production line equipment refers to equipment used to extract oil from rice bran. Rice bran is a byproduct generated during processing. It is rich in nutritional value and oil and can be used as edible oil, industrial oil, and biofuel. The following are some common rice bran oil processing equipment:

1. Rice bran oil extractor: This is equipment used to extract oil from rice bran. It usually includes processes such as washing, drying, peeling, crushing, and pressing.

2. Rice bran oil evaporator: After extracting oil, an evaporator can be used to remove the solvent in the oil. This process is usually done by heating the oil to evaporate the solvent to obtain pure rice bran oil.

3. Rice bran oil refining equipment: These equipment are used to remove impurities and impure substances in rice bran oil, such as acids, alkalis, and colors. Common refining equipment includes deacidification, deodorization, and decolorization equipment.

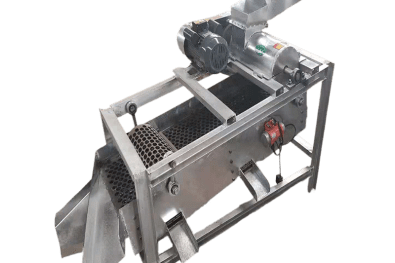

4. Rice bran oil filtration equipment: Used to filter rice bran oil and remove impurities and solid particles in the oil. Filtering equipment often uses filter screens or filter paper. These equipment can usually choose the appropriate scale and model according to the processing volume and processing technology. When choosing rice bran oil processing equipment, factors such as processing capacity, efficiency, quality control and safety need to be considered.

In addition, maintenance and upkeep of equipment are also important aspects to ensure the normal operation of equipment and improve processing efficiency. When it comes to rice bran oil processing equipment, there are other equipment and processes to consider:

5. Rice bran drying equipment: Before oil extraction, rice bran usually needs to be dried to remove moisture to avoid affecting the oil extraction effect. Common drying equipment includes ovens, dryers, etc.

6. Oil press: It is used to press the crushed rice bran to separate the oil from the solid matter. There are two common oil presses: physical oil presses and chemical oil presses. Physical oil presses extract oil through mechanical pressing, while chemical oil presses use solvents for extraction.

7. Residue processing equipment: After extracting oil from rice bran, the remaining residue is called rice bran residue. In order to effectively utilize these residues, you can consider using residue processing equipment, such as rice bran residue dryers, rice bran residue pelletizers, etc., to convert them into a form that can be used for feed, biomass fuel or other products.

8. Oil storage equipment: In order to maintain the quality of rice bran oil and extend its shelf life, appropriate oil storage equipment, such as tanks or containers, is required. These equipment should be airtight and corrosion-resistant.

Please note that the selection and configuration of rice bran oil processing equipment may vary depending on specific processing needs and budget. It is recommended to consult relevant professionals or suppliers to ensure that the equipment is selected to suit your situation and ensure its safe and efficient operation. There are some other aspects to consider when it comes to rice bran oil processing equipment:

9. Automated control system: Some advanced rice bran oil processing equipment may be equipped with an automated control system, which can achieve fully automatic or semi-automatic production process control, improve production efficiency and reduce manual operation.

10. Energy consumption and environmental factors: Choosing equipment with high energy efficiency and low energy consumption can reduce production costs and reduce negative impacts on the environment. At the same time, understanding whether the equipment meets environmental standards is also an important consideration.

11. Reliability and maintenance: The reliability of equipment is a key factor in ensuring production continuity and stability. Understanding the after-sales service and maintenance support provided by the supplier, as well as the maintenance requirements and repair cycles of the equipment, will help the decision-making process.

12. Equipment flexibility: Considering possible process changes or market demand changes in the future, it is a wise choice to choose equipment with a certain degree of flexibility that can adapt to different types of rice bran or be modified when necessary.

In summary, choosing suitable rice bran oil processing equipment requires comprehensive consideration of processing needs, production capacity requirements, quality control, energy consumption, environmental standards and supplier reliability. It is recommended to conduct sufficient market research, communication and consultation before making a decision, and evaluate the advantages and disadvantages of different equipment to make a suitable choice.