Peanut oil is a cooking oil that we often see and eat in our daily lives. The extraction methods of peanut oil are the pressing method and the leaching method. Due to different processes, the quality of the final product oil is also different. But what is currently sold on the market is refined, so the question arises: Does peanut oil have to be processed by refining equipment?

Some people think that the peanut oil produced by the pressing method already meets the national first-class peanut oil standards and does not need to be refined. If you want to obtain high-quality peanut oil and increase the value of peanut oil, you only need to freeze and filter the peanut oil; Peanut oil produced by the leaching method needs to be refined because the leached peanut oil contains various impurities, such as peptized impurities, free fatty acids, pigments and odorous substances, etc., which need to be removed using peanut oil refining equipment to obtain products that meet national standards. of peanut oil.

The purpose of refining is to remove harmful and unhelpful impurities in crude oil and retain the beneficial parts, such as tocopherols. Refining is very necessary to obtain high-standard and high-quality peanut oil. The reasons are:

First of all, the refining equipment adopts advanced physical separation technology, which can control the oxidative rancidity of peanut oil, slow down the rancidity of refined peanut oil, remove impurities in the oil, and use low-temperature, anaerobic, light-breaking, antioxidants, etc. This section can effectively reduce the color of the oil. , the color of peanut oil is clearer and more transparent, improving the quality.

Secondly, there are many harmful elements in crude oil, such as polycyclic aromatic compounds, aflatoxins, and pesticide residues. These harmful substances will have a great impact on people’s health. After being processed by the refining equipment, the quality of the peanut oil is guaranteed, and the smell of the peanut oil becomes fresh, natural, and more attractive.

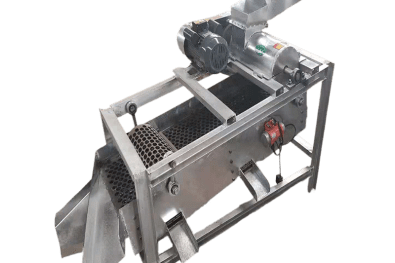

Then, peanut oil before refining contains a certain amount of wax, which has a high melting point, poor solubility, and is not absorbed by the human body. When the oil temperature decreases, it will crystallize and make the oil turbid, affecting the appearance of the product. Therefore, the refining and dewaxing equipment will use low-temperature cooling crystallization, crystal growth, filtration, and other methods to separate and remove the wax in the edible oil, which can effectively improve the appearance and make the food healthier.

Finally, the complete set of peanut oil refining equipment is also energy-saving and environmentally friendly, and the equipment is also equipped with efficient filtration and wastewater treatment systems, which can effectively remove grease and impurities in wastewater. Not only does the quality of peanut oil improve, but it also meets emission standards and Protects the safety and health of the surrounding environment.

More importantly, refined edible oil meets national standards and is superior to unrefined refined oil in terms of peanut oil quality and storage. Therefore, if oil mills or investors want to produce high-quality and high-standard peanut oil, the refining section cannot be ignored and needs to be paid attention to!

It is precisely because refined peanut oil has passed the quality inspection of relevant departments that it can be sold on the market, so we can often see them in supermarkets, which improves the quality and safety of edible oil!