Building a 50-ton per day (TPD) peanut oil mill business plant in Egypt involves a comprehensive approach with considerations for scale, technology, compliance, and operational efficiency. Here’s an outline to help guide the development of such a plant:

1. Business Strategy and Feasibility

- Market Analysis: Examine the demand for peanut oil in Egypt and the broader region, identifying key markets, competitors, and trends. Consider the scale of production and potential revenue.

- Feasibility Study: Evaluate the feasibility of a 50 TPD plant, including capital investment, operational costs, and expected returns. Address risks and identify key success factors.

- Business Plan: Develop a detailed business plan that covers financial projections, operational goals, marketing strategy, and growth potential.

2. Location and Infrastructure

- Location: Choose a site that is strategically located near peanut-producing areas and has good access to transportation networks. Consider logistics for raw material sourcing and product distribution.

- Infrastructure: Ensure the site has access to reliable utilities, such as power, water, and waste management. Plan for infrastructure to support the larger scale of operations, including storage, loading, and packaging areas.

3. Advanced Equipment and Technology

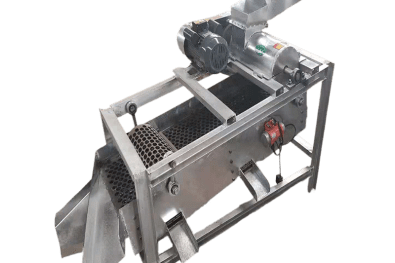

- Extraction Equipment: For a 50 TPD operation, you will need robust equipment like large-capacity screw presses, decorticators, and oil extraction systems. Choose reputable manufacturers for quality and reliability.

- Pre-processing and Post-processing: Include machinery for cleaning, dehusking, drying, and oil filtration. This ensures efficient processing and high-quality oil production.

- Automation and Control Systems: Implement automation to manage large-scale operations efficiently. Use advanced control systems for temperature, pressure, and quality monitoring.

peanut oil production line

4. Raw Material Sourcing

- Peanut Sourcing: Establish strong relationships with peanut suppliers or farmers’ cooperatives. Consider long-term contracts to ensure a stable supply of raw materials.

- Quality Control: Implement strict quality control measures for incoming peanuts. Use grading systems to ensure consistent quality for optimal oil extraction.

5. Regulatory Compliance and Safety

- Permits and Licenses: Obtain all necessary permits and licenses from local and national authorities. Ensure compliance with regulations regarding food processing, safety, and environmental impact.

- Safety Standards: Implement comprehensive safety protocols for plant workers, including training, safety equipment, and emergency procedures. Regularly conduct safety audits.

6. Workforce and Training

- Hiring: Recruit skilled workers with experience in large-scale oil processing, machinery operation, and quality control. Consider a mix of technical and operational staff.

- Training Programs: Provide ongoing training for all employees to ensure safety and operational efficiency. Emphasize quality control and equipment maintenance.

7. Operational Efficiency and Quality Control

- Operational Workflow: Design an efficient workflow from raw material intake to oil extraction, filtration, and packaging. Ensure seamless transitions between stages to maximize productivity.

- Quality Assurance: Implement a robust quality assurance program to maintain high standards for the extracted oil. Regular testing and quality monitoring are essential.

8. Marketing and Distribution

- Marketing Strategy: Develop a comprehensive marketing strategy to promote your peanut oil brand. Consider unique selling points, branding, and customer engagement initiatives.

- Distribution Channels: Establish partnerships with distributors and retailers to ensure broad market reach. Consider direct-to-consumer channels and online sales to expand your customer base.

9. Environmental Sustainability

- Waste Management: Implement effective waste management practices to minimize environmental impact. Consider recycling peanut shells and other byproducts.

- Sustainability Practices: Explore options for renewable energy, water conservation, and reducing the plant’s carbon footprint.

10. Continuous Improvement and Expansion

- Performance Monitoring: Continuously monitor the plant’s performance and gather feedback for improvement. Implement changes to enhance efficiency and quality.

- Innovation and Expansion: Stay updated with industry trends and explore new technologies. Consider opportunities for expanding production capacity or diversifying into related products.

Video: 50TPD Peanut Oil Pressing Technology

By following this comprehensive approach, you can establish a successful 50 TPD peanut oil mill business plant in Egypt that meets market demands, operates efficiently, and adheres to regulatory requirements.